Improved safety with DSI Trusses

San Juan Mine, Farmington, New Mexico, USA

Coal mine roof trusses have been proven, over the years, to be helpful in many difficult conditions. Traditionally, a truss consists of two anchor bolts installed at opposing forty five degree angles on either side of the mine entry, two transition coupler assemblies, and a cross member to connect the angle bolts. When the cross member is tensioned, the resultant force introduces compressive forces into the mine roof, effectively decreasing the span of rock that is in tension in the mine roof.

Within the last seven or eight years, cable trusses as well as bar-cable trusses have been introduced. The main difference is that the cross tension member consists of one or two lengths of post-tensioning strand, typically 270-ksi 0.6" strand, with a minimum tensile strength of 58,600 lbs (260 kN). The tensioning member is tensioned using a portable hydraulic tensioning unit.

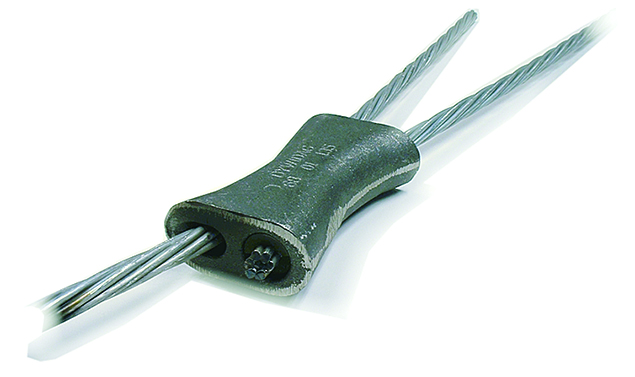

DSI, at the request of James Pile, geotechnical engineer at BHP Billiton San Juan Mine near Farmington, New Mexico, developed a new bar-cable truss system. It consists of two resin encapsulated roof bolts, DSI threadbar #7, eight feet long, two truss couplers, installed with the bolts, two lengths of strand with wedge and barrel assemblies pre-seated on one end, a center "dog-bone" style transition coupler, and two sets of wedges used to tension and seat the cross member after installation of the truss.

The simple design eliminates many small parts common with other similar truss systems. The key advantages are fewer pieces required to assemble the truss when being installed, and the associated safety of the operator because it is no longer necessary for the operator to stretch out at awkward angles, exposing himself to unsupported roof and rib conditions.

The two angled roof bolts are installed with the truss couplers, then the cross members are easily installed near the center of the entry, where the operator can work more comfortably, and be protected from dangerous conditions. The cast transition coupler allows the two opposing tension members to align themselves when tensioned, and the need for extra wedge barrels is eliminated because the wedge sets are seated into the transition coupler.