Safe Underground Impermeabilization: DSI Underground supplies Mineral Bond Silicate Resin to the Frasers Mine

The Frasers Underground Mine is located 100km north of Dunedin on New Zealand’s South Island. At this location, OceanaGold extracts gold by underground mining. At the mine, several previously mined areas had to be sealed off with rated water retaining bulkhead seals. Originally, large and expensive plug seals were planned, the costs for which would have been disproportionately high. Mastermyne, a specialist mining service provider, suggested using mineral bond urea silicate resin to consolidate the ground, reducing the thickness of the seals and overall costs.

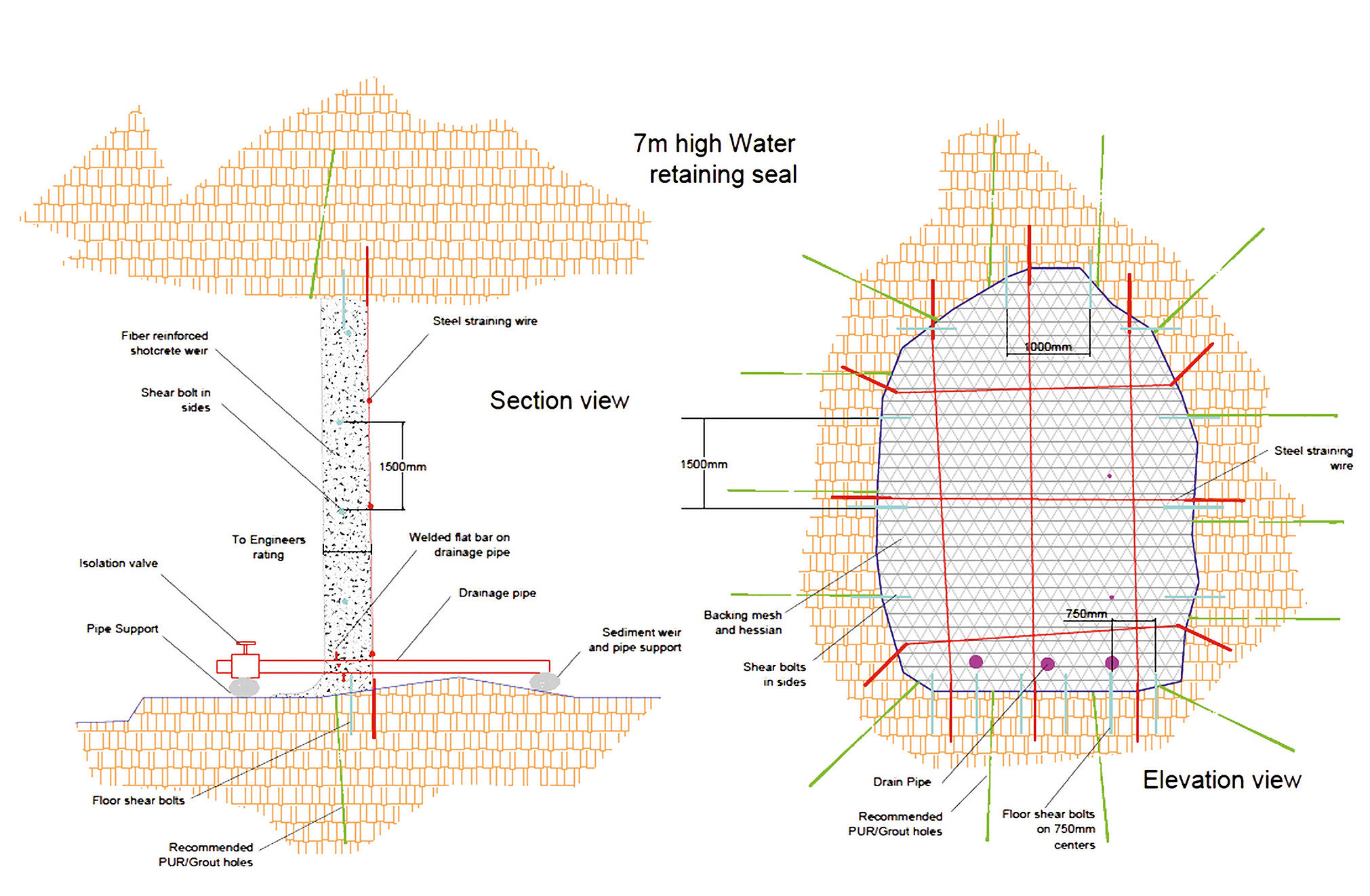

In this solution, a 7.1m high by 6m wide water retaining bulkhead containing water drain pipes was built at one of the stopes. The old trial stope site required a 2m high and 6m wide water retaining dam wall. In a third stope, an old decline had to be sealed off that was allowing blast fumes to enter the underground working after an embankment slip in the surface mine.

The problem was that fractured ground around the drive area where the two bulkhead walls were to be built would allow water to ingress through the broken ground with a otential to flood areas of the mine and render the bulkhead seals ineffective.

Working with Mastermyne, DSI Underground Australia suggested pumping Mineral Bond Urea Silicate Resin into the strata around the drive to consolidate the ground and eliminate the water passage around the bulkhead seal sites. Mineral Bond was chosen as it is a nonexpanding resin which is unaffected by water, remains flexible and develops a strength of 40mPa. Holes were drilled to a depth of 3m around the perimeter of the drive directly at the seal site location. The holes were packed off using BVS40 borehole packers attached to R28 GRP bolts which were installed into the holes to provide additional strength.

The first stope required a water retaining bulkhead seal with 14 injection holes evenly spaced around the perimeter of the drive.

This site consumed 520l of Mineral Bond placed in the backs and hanging wall shoulder where the ground appeared to have a higher fracture network. The old trial stope site required 6 injection holes around the lower perimeter of the drive. This site consumed 1,030l of Mineral Bond in the lower walls and floor area, where the ground was badly fractured.

On both sites, the product showed good migration through the ground with leakage from the area appearing up to 4m away from the borehole collar. Both the injection work and seal construction were safely completed within acceptable timeframes.